Following a request from the Ordre des Pharmaciens du Québec (OPQ), the pharmacy department of a major Montreal hospital was asked to implement a pressure monitoring and notification system for their sterile preparation areas and hoods.

Having already benefited from ATEK’s services for temperature monitoring, the responsible pharmacist contacted us to see if we could provide a solution meeting the OPQ’s requirements.

Regulatory Context

The Ordre des Pharmaciens du Québec requires greater rigor in managing sterile areas to reduce risks:

- Contamination risks to sterile products and ensuring patient safety for those receiving these medications

- Health and safety risks for staff handling potentially carcinogenic or teratogenic hazardous drugs

To this end, the OPQ requires “the implementation of procedures and safety measures (e.g., monitoring the pressure gradient in the cleanroom used to prepare hazardous drugs).” This means maintaining pressure records with complete traceability.

The Existing Infrastructure Challenge

Most healthcare facilities in Quebec, whether recently renovated or newly constructed, use the Building Automation System (BAS) to manage pressures in sterile areas. However, pharmacists who are required to maintain records often face obstacles imposed by administration or the company managing the control system when trying to access their data.

The Facility’s Particular Situation

The pharmacy department oversees several sterile areas spread across different hospital pavilions, both recent and older.

For older areas: Differential pressure controllers are installed locally, but these controllers are not connected to the building control system. After evaluation, it was not economical to connect these areas to the existing control system.

For newer pavilions: The company managing the control system did not allow access to room differential pressure data — a frustrating but unfortunately common situation.

For hoods: The supervised hood fleet is varied, and the hoods only have local pressure or flow indicators. There was no option other than manual reading of pressure gauges — a time-consuming and error-prone approach.

The ATEK Solution

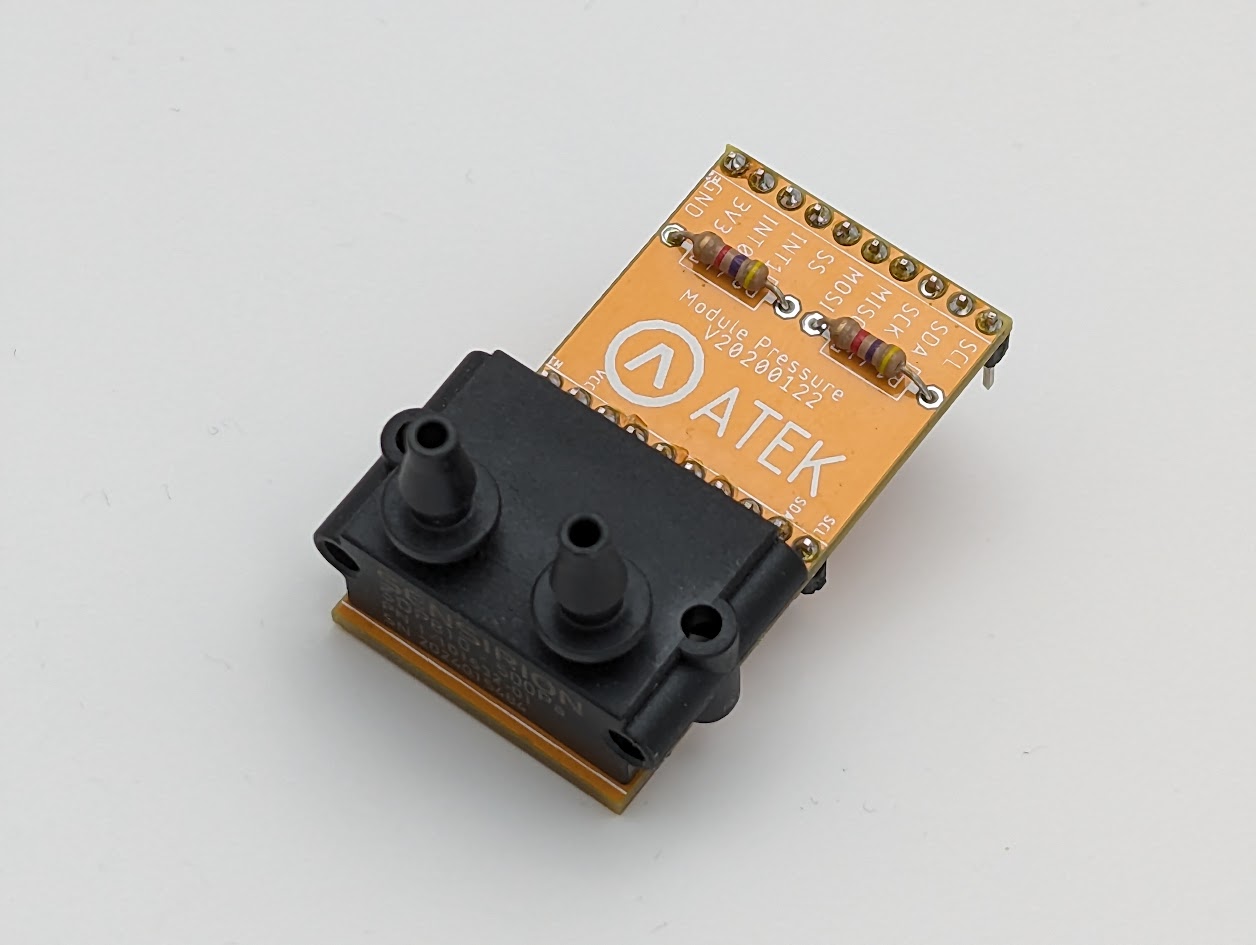

The pharmacy was already using ATEK’s system to monitor approximately sixty temperature and humidity points to comply with regulatory requirements, so they invited us to propose an integrated solution.

Project Scope

Installation of pressure monitoring equipment for:

- 12 sterile rooms and anterooms — continuous pressure gradient monitoring

- 14 hoods — automated monitoring replacing manual readings

Solution Benefits

-

Data Centralization — All pressure measurements accessible on a single platform, alongside existing temperature and humidity data

-

Real-time Alerts — Immediate notification of abnormal pressure variations, enabling rapid intervention

-

Complete Traceability — Automatic records compliant with OPQ requirements, with timestamps and audit trails

-

BAS Independence — No longer dependent on building control system managers for data access

-

Quick ROI — Elimination of manual reading hours and reduced non-compliance risks

Conclusion

This project illustrates how ATEK can integrate with existing infrastructure, even when complex and heterogeneous, to provide a complete and compliant monitoring solution. Hospital pharmacists regain control of their compliance data without depending on administrative or technical constraints of the building control system.

For detailed regulatory requirements, see our compliance guides on OPQ sterile hazardous preparations and USP 797 sterile compounding. Explore ATEK’s hospital pharmacy monitoring and cleanroom solutions.

References: