In the life sciences industry, pharmaceutical sector, research laboratories, and healthcare facilities, environmental monitoring is more than a best practice—it is a regulatory requirement.

Parameters such as temperature, humidity, differential pressure, carbon dioxide, and oxygen levels must be continuously monitored, thoroughly documented, and readily accessible at all times. A missed reading or error can lead to serious financial, scientific, or health-related consequences.

But what if this obligation could be turned into a strategic advantage? With an automated monitoring solution like the one developed by ATEK, technology becomes a silent, reliable, and consistent guardian. It ensures regulatory compliance, enhances operational efficiency, reduces losses, and strengthens overall quality.

Standardizing Quality: Reliability and Consistency Over Time

In critical environments, even a minor error can compromise weeks or months of work. A missed manual reading, a misreported value, or an unmonitored piece of equipment can have significant consequences.

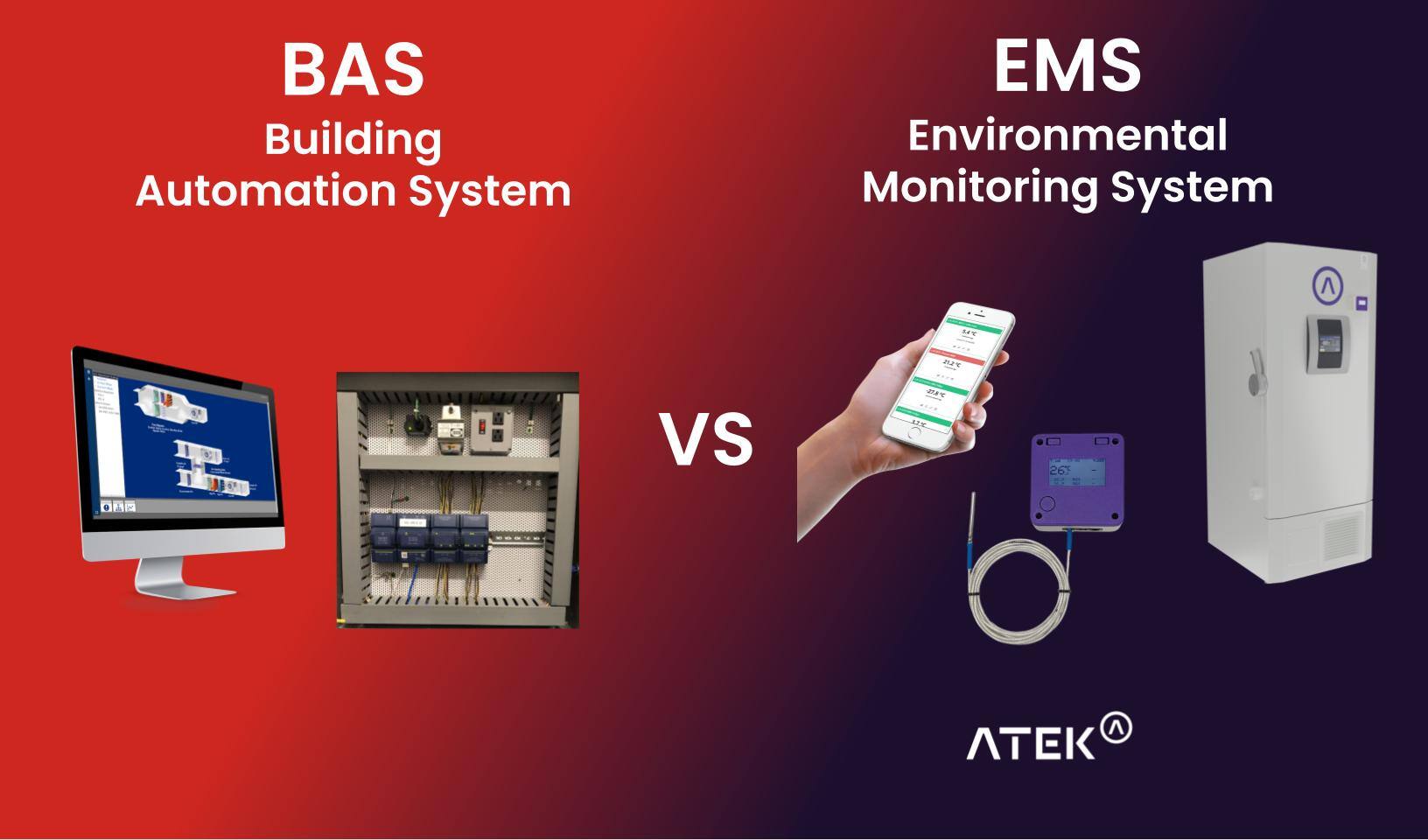

An automated monitoring system enables process standardization. Using smart, connected sensors, the system automatically collects and transmits precise environmental data—such as temperature, humidity, or pressure—at regular intervals. This data is securely sent to a cloud-based platform with no manual intervention required.

Each reading is timestamped, geo-tagged, and stored in a complete historical record. By eliminating human error, data reliability is improved, operational quality is maintained, and exemplary traceability is ensured during audits.

Simplifying Regulatory Compliance: Always Audit-Ready

Highly regulated industries must meet strict standards such as Good Manufacturing Practices (GMP), ISO 17025, Health Canada guidelines (GUI-0069), and FDA 21 CFR Part 11.

ATEK’s automated monitoring system turns compliance into a streamlined, automated process.

Through a centralized dashboard, users can view the real-time status of all equipment, monitor environmental metrics, track anomalies, and access complete historical data. Centralized information supports multi-site management and trend analysis.

Compliance reports are generated automatically in PDF or Excel formats according to your desired frequency. Each event is logged in a secure audit trail, ensuring full and traceable documentation.

The system also simplifies calibration and validation management. Automated reminders notify you of upcoming interventions. Certificates and records are securely archived, significantly reducing administrative workload.

Reducing Losses: Acting Before It’s Too Late

In critical environments, a single equipment failure can result in substantial financial losses. A low-temperature freezer failure during a holiday or weekend can lead to the destruction of invaluable biological samples or pharmaceutical products.

To prevent such incidents, ATEK’s automated monitoring system features a multi-level alert management protocol. When a critical threshold is exceeded, an alert is sent to the assigned contact. If there is no response within a set timeframe, the alert escalates automatically to the next level, ensuring a timely response.

Alerts are fully customizable based on your operational structure and preferences. Notifications can be sent via text message, email, automated phone call, or pager if necessary. Alert schedules can also be configured to match work shifts and monitoring priorities.

Every critical asset is continuously protected—incubators, −80 °C freezers, cleanrooms, cold storage units, environmental chambers, and medical gas networks. This level of oversight significantly minimizes the risk of material loss and non-compliance.

Saving Time and Increasing Efficiency: Streamlining Daily Operations

In addition to improving compliance and safety, the automated monitoring system enhances day-to-day operations. Automating environmental data logging eliminates manual rounds, spreadsheets, and human errors.

Collected data is automatically integrated into your internal quality management systems or enterprise software. Quality managers and supervisors can access, review, and validate the data remotely through a secure web interface.

Analysis reports can be generated on demand or according to a predefined schedule and easily shared with auditors or partners. This translates into considerable time savings during audits or compliance reviews.

ATEK also offers a managed maintenance service. Our teams handle installation, sensor calibration, software updates, and technical support—allowing your internal resources to focus on core operations with the assurance of reliable system performance.

A Scalable and Interoperable Solution

Every organization has its own structure, culture, and compliance needs. That’s why ATEK’s solution is designed to be fully modular, scalable, and interoperable.

It can be deployed on a single site or across a complex network of facilities, all while maintaining centralized supervision. The system integrates seamlessly with your existing tools—whether it’s ERP software, quality control systems, or maintenance platforms.

This flexibility allows the solution to adapt to your current and future needs. Whether facing regulatory changes, expansion, or organizational restructuring, the system can be reconfigured without disrupting your infrastructure.

Toward Proactive, Sustainable Critical Environment Management

One of the most undervalued benefits of an automated monitoring system is its ability to shift your approach—from reactive incident management to proactive risk prevention. By embedding real-time, reliable environmental data into your decision-making processes, you not only boost responsiveness but also strengthen your ability to anticipate and avoid issues before they arise.

Thanks to comprehensive, timestamped data history, it becomes possible to detect hidden trends, implement corrective actions early, or predict equipment wear. This type of preventive analysis—closely tied to digital transformation—provides a tangible competitive advantage, especially in regulated environments.

Furthermore, during a regulatory audit or surprise inspection, the presence of an intelligent monitoring system reassures authorities. Fast access to certified, traceable, and secure data demonstrates a strong commitment to compliance, precision, and quality. It could be the difference between a minor comment and a major non-conformity.

By implementing a solution like ATEK’s, you are investing in more than just a sensor system—you’re deploying a digital safety net designed to protect your facilities, your products, and your reputation in the long term.

Adopt a Monitoring System That Meets Your Standards

An automated monitoring system is no longer a luxury or a simple compliance tool. It’s a strategic lever for performance. By choosing a proven, secure solution built for critical environments, you’re investing in the continuity of your operations, the safety of your products, and the reliability of your data.

With ATEK, you benefit from robust, adaptable technology, personalized support, and local expertise aligned with the needs of organizations operating in regulated industries.

Learn more about the regulations driving automated monitoring requirements, including FDA 21 CFR Part 11, Health Canada GUI-0069, and ISO 17025. See how ATEK serves biotech and pharma environments.

Smart monitoring is a choice in favor of excellence, precision, and peace of mind.